celluloseIn particular, modified cellulose ethers such as HPMC, MC, etc. are used in building materials construction by regulating the water retention, rheological properties, and opening time of the materials, which puts forward targeted requirements for the construction process to fully utilize their performance advantages and avoid defects. The specific special requirements are as follows:

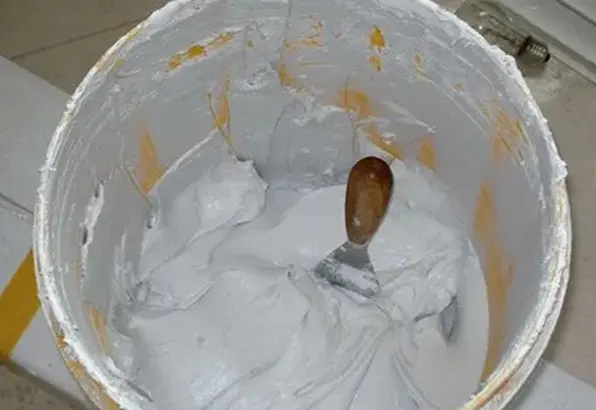

1、 Material preparation stage: Control stirring and proportioning to ensure uniform dispersion of cellulose

Mixing speed and time: avoid "clumping" or excessive shearing

Cellulose ether is in powder form, and if directly added to water, it is prone to form "fish eye shaped" clusters due to rapid surface wetting (internal drying, external swelling). It needs to be dry mixed with aggregates (sand, gypsum powder, etc.) before adding water and stirring (stirring speed 100-300 revolutions per minute).

The stirring time should be moderate (usually 3-5 minutes): too short can cause uneven dispersion, and local water retention is too strong (prone to bubbles) or insufficient (prone to cracking); If it is too long, it may damage the cellulose molecular chains due to excessive shear force, reducing thickening and water retention effects.

Accurate control of water addition: matching the water retention capacity of cellulose

celluloseSignificantly improve the water retention of the material, and the amount of water added must strictly follow the formula (error ≤ 5%):

Excessive water addition: The slurry is too thin, and the thickening effect of cellulose is diluted, which can lead to sagging (such as putty construction), layering (such as gypsum mortar), and a decrease in strength after hardening.

Insufficient water addition: The viscosity of the slurry is too high, making it difficult to mix evenly, and the "washboard effect" (such as uneven surface of the plaster layer) is prone to occur during construction.

2、 Construction environment: strict management of temperature, humidity, and ventilation

Temperature control: avoid high and low temperature construction

The optimal construction temperature is 5-35 ℃:

When the temperature is below 5 ℃, the hydrogen bonding strength between cellulose and water weakens, the water retention decreases, and the hydration/hardening rate of the material slows down. Therefore, it is necessary to extend the curing time (usually by more than 50%) and avoid construction before freezing (water freezing will damage the cellulose network).

When the temperature is higher than 35 ℃, the water evaporation rate exceeds the water holding capacity of cellulose, and the slurry is easy to dry quickly, leading to "false condensation" (crust on the surface but not hardened inside) during construction, which is easy to crack later. It is necessary to reduce the ambient temperature through shading, spray humidification and other methods.

Humidity regulation: Balancing water retention and drying speed

High humidity (>85%) environment: Cellulose has strong water retention, and the material dries slowly, which may cause later moisture regain and mold growth (such as interior wall putty). It is necessary to strengthen ventilation (such as turning on a fan) or extend the interval time (such as extending the putty scraping interval from 24 hours to 48 hours).

Low humidity (<30%)+strong wind environment: Moisture loss is too fast, and cellulose cannot be completely controlled to dry and shrink. After construction, it is necessary to cover it with plastic film to keep it moist (such as plaster layer), or apply it thinly in multiple times (such as latex paint base putty) to avoid cracking caused by one-time thick coating.

3、 Construction operation: Adapt to the rheological properties of cellulose

Scratching/plastering process: controlling thickness and tool selection

celluloseThe thickened slurry has "thixotropy" (becoming thinner when stirred and thicker when left to stand), and during construction, it is necessary to:

The thickness of a single scraping should not be too large (such as putty ≤ 2mm, plastering layer ≤ 10mm), otherwise uneven drying shrinkage may lead to peeling and cracking. Layered construction is required, and the next layer should be applied after each layer is dry.

Use tools such as hard brushes and steel spatulas: Cellulose increases the viscosity of the slurry, while soft tools can easily cause surface roughness. Hard tools can ensure a smooth surface (by maintaining the consistency of the slurry after it is left to stand).

Laying and Forming: Adapting to the Operating Rhythm of Opening Hours

Cellulose prolongs the opening time of materials (such as extending the drying time of tile adhesive from 10 minutes to 20 minutes), but the operation needs to be completed before initial setting:

When tiling tiles, if the opening time is exceeded, the surface of the adhesive will form a "film" due to the water retention of cellulose, which will reduce the bonding strength. It is necessary to remove the old adhesive and reapply it.

When gypsum board is poured and formed, it needs to be spread and compacted within the initial setting time controlled by cellulose (usually 30-60 minutes) to avoid uneven thickness of the board due to the hardening of the slurry.

4、 Maintenance stage: Ensure stable solidification of cellulose network

Moisturizing care: avoid sudden loss of moisture

The material structure formed by cellulose assistance (such as mortar, gypsum) relies on moisture to complete hydration in the early stage of hardening, and requires:

Within 1-3 days after plastering/pouring, sprinkle 1-2 times a day (or cover with damp cloth) to ensure the surface is moist and prevent micro cracks in the cellulose network due to dehydration shrinkage.

Thin layer materials such as putty and paint: Avoid strong wind blowing directly, close doors and windows and let them dry naturally in the shade. Utilize the water holding capacity of cellulose to slowly release moisture and reduce shrinkage stress.

Post drying: prevent performance degradation caused by excessive drying

The drying speed needs to be uniform: for example, after the construction of external wall insulation mortar, if the ventilation is suddenly too strong, the surface moisture will quickly dissipate, while the interior will still be relatively moist due to cellulose water retention, which can easily form internal stress and cause hollowing. It is necessary to gradually increase the ventilation intensity (such as opening the windows half first and fully opening them after 3 days).

summary

The core requirements of cellulose for construction technology are concentrated in four aspects: "uniform dispersion, environmental adaptation, rhythm control, and moisturizing maintenance". Its essence is to coordinate the water retention and thickening characteristics of cellulose with the hydration/hardening laws of materials, to avoid problems such as cracking, hollowing, and insufficient strength caused by improper construction. In practical operation, process parameters need to be adjusted according to the type of cellulose (such as the difference in water retention between HPMC and MC) and specific materials (such as putty, gypsum board, mortar) to maximize their performance advantages.

TEL:+86 (0311) 8444 9786

Email:sales@double-bulls.com

Email:Export@double-bulls.com

Address:No.9 Weisi Road, Jinzhou City Eco-nomic Development Zone, Shijiazhuang City, Hebei Province.

Website

Brochure

Video