In personal cleaning products such as shampoo and shower gel,cellulose(Usually cellulose derivatives, such as hydroxyethyl cellulose, hydroxypropyl methyl cellulose, etc.), as important additives, through unique molecular structure and physical and chemical properties, achieve the effect of thickening and stabilizing foam. The specific mechanism is as follows:

1、 Thickening effect: increases system viscosity and improves texture during use

The viscosity of shampoo and shower gel is the key factor affecting the user experience (such as avoiding excessive fluidity caused by being too thin and difficult to control the dosage during use). The thickening principle of cellulose derivatives is mainly based on the following two points:

Hydration and entanglement of molecular chains

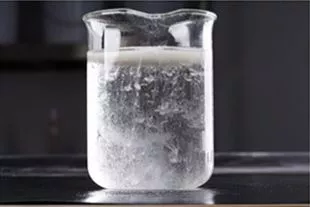

Cellulose derivatives contain a large number of hydrophilic groups (such as hydroxyl and ether groups) on their molecular chains, which can form hydrogen bonds with water molecules, rapidly absorb water, expand, and disperse in the system. The expanded molecular chains intertwine with each other, forming a three-dimensional network structure that acts as a "molecular skeleton" to impede the flow of liquid, thereby significantly increasing the viscosity of the system.

For example, after the hydroxyethyl cellulose (HEC) is dissolved in water, the molecular chains stretch and interweave with each other. Even if the addition amount is only 0.1%~1%, the viscosity of the system can be increased from tens of centipoises to thousands of centipoises, making the product an ideal paste or lotion.

Synergistic effect with surfactants

Cleaning products typically contain anionic surfactants such as sodium cinnamyl sulfate and cocoamidopropyl betaine, which form micelles in water. The molecular chains of cellulose derivatives can adsorb on the surface of micelles and bind with them through electrostatic attraction or hydrophobic interactions, further enhancing the structural stability of the system and indirectly increasing viscosity.

This synergistic effect can also avoid the viscosity decrease caused by temperature changes (such as high temperatures in summer), allowing the product to maintain stable consistency in different environments.

2、 Stabilizing foam: prolonging the duration of foam and improving the cleaning experience

Foam is an important feature of cleaning products (consumers often associate foam richness with cleaning power), but foam is easy to dissipate due to gravity, liquid film rupture and other reasons. Cellulose derivatives can stabilize foam by the following ways:

Enhance the mechanical strength of foam liquid film

The core of foam is the structure of "gas is wrapped by liquid film", and the toughness of liquid film determines the stability of foam.celluloseThe molecular chains of derivatives can be adsorbed on the surface of foam liquid film to form an "elastic protective film":

The hydrophilic groups in the molecular chain are oriented towards the aqueous phase, while the hydrophobic parts are oriented towards the gas phase. The steric hindrance effect prevents the rapid loss of water in the liquid film, delaying the thinning and rupture rate of the liquid film.

At the same time, the winding effect of molecular chains makes the liquid film more elastic, and it is not easy to break even under external forces (such as rubbing, water flow impact), thus extending the duration of foam.

Adjust surface tension to promote uniform distribution of foam

Although cellulose derivatives are not surfactants (their own foaming ability is weak), they can cooperate with surfactants in the system to reduce the surface tension of the liquid, so that foam is easier to generate and more evenly distributed (to avoid rapid burst of large bubbles and sparse small bubbles).

For example, in shampoo, cellulose derivatives can help the surfactant form a fine, durable foam, enhance the wrapping of scalp and hair, and enhance the smoothness of cleaning.

summary

celluloseDerivatives are multifunctional regulators in shampoo and shower gel: they achieve thickening through the hydration entanglement of molecular chains and the synergistic action of surfactants, ensuring that the product has appropriate viscosity and stability; By strengthening the strength of foam liquid film and adjusting the surface tension, the foam can be stabilized and the richness and durability of foam can be improved. Its function not only improves the user experience of the product, but also reduces the amount of other thickeners (such as high molecular polymers) used, in line with the trend of gentle cleaning.

TEL:+86 (0311) 8444 9786

Email:sales@double-bulls.com

Email:Export@double-bulls.com

Address:No.9 Weisi Road, Jinzhou City Eco-nomic Development Zone, Shijiazhuang City, Hebei Province.

Website

Brochure

Video