In oil extraction,celluloseAnd its derivatives (such as hydroxyethyl cellulose, carboxymethyl cellulose, etc.) are important oilfield chemical additives, mainly improving the performance of drilling fluids, fracturing fluids, and oil displacement agents, indirectly or directly increasing oil recovery rates. Its function and mechanism are as follows:

1、 As a drilling fluid additive: ensuring drilling safety and reservoir protection

During the drilling process, drilling fluid needs to maintain wellbore stability, carry rock debris, and protect the reservoir (to avoid blocking oil and gas channels). Cellulose substances mainly play a role by thickening and reducing filtration:

Thickening effect

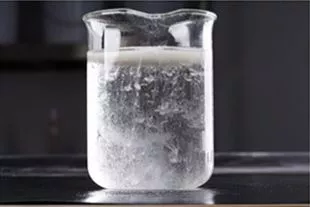

Cellulose molecular chains contain a large number of hydroxyl groups, which can form a three-dimensional network structure through hydrogen bonding interactions in water, significantly increasing the viscosity of drilling fluids. A higher viscosity can enhance the ability of drilling fluid to carry rock debris, prevent rock debris from settling and blocking the wellbore, and stabilize the wellbore wall (especially in loose sandstone reservoirs, which can reduce the risk of wellbore collapse).

Filtration reduction effect

Cellulose molecules can adsorb at the interface between drilling fluid and formation rocks, forming a dense "filter cake" that reduces the penetration of drilling fluid into the reservoir (filtration loss). This can prevent the pores of the reservoir rock from being blocked by solid particles in the drilling fluid, protect the integrity of the oil and gas channels, and preserve a smooth flow path for subsequent oil recovery.

2、 As a fracturing fluid additive: improving fracturing effectiveness and expanding reservoir conductivity

In the exploitation of low-permeability reservoirs such as shale gas and tight oil, hydraulic fracturing is a key technology (by fracturing the reservoir rock under high pressure to form a fracture network to improve oil and gas fluidity),celluloseDerivatives are the core additives of fracturing fluids:

Thickening and sand carrying effect

Fracturing fluid needs to carry proppants (such as quartz sand) into the crack, while cellulose derivatives (such as hydroxypropyl guar gum often compounded with cellulose) increase the viscosity of the fracturing fluid through thickening, allowing the proppants to be uniformly suspended and pushed deep into the crack. If the viscosity is insufficient, the proppant will settle prematurely, unable to effectively support cracks, resulting in crack closure and reduced flow capacity.

Temperature and salt resistance regulation

Deep reservoirs often face high temperatures (>100 ℃) and high mineralization (containing a large amount of Ca ² ⁺, Mg ² ⁺), and ordinary cellulose is prone to degradation or loses its thickening ability due to ion interference. By chemical modification (such as introducing ethyl, carboxymethyl and other functional groups), the temperature and salt resistance of cellulose can be enhanced, ensuring that the fracturing fluid can maintain stable viscosity under special conditions and guaranteeing the fracturing effect.

Gel breaking and flowback performance

After fracturing is completed, cellulose based fracturing fluid needs to be "broken" (such as enzymatic hydrolysis or oxidation) to reduce viscosity, in order to flow back from the crack and avoid residual blockage of the crack. Cellulose derivatives can be designed as a "controllable gel breaking" system that rapidly degrades after the support agent is in place, reducing damage to the reservoir.

3、 As a tertiary oil recovery and displacement agent: improving oil displacement efficiency

After primary oil recovery (natural energy) and secondary oil recovery (water flooding), 60% to 70% of the crude oil still remains underground. For tertiary oil recovery (chemical flooding, polymer flooding, etc.), additives are needed to improve the oil recovery rate. Cellulose derivatives mainly function as polymer flooding agents:

Improve the viscosity of the displacement fluid and improve the flowability ratio

During the process of water flooding, due to the much lower viscosity of water compared to crude oil, it is prone to the "fingering phenomenon" (water rapidly flows along high permeability channels, bypassing a large amount of crude oil). Cellulose derivatives (such as partially hydrolyzed polyacrylamide often compounded with cellulose) can significantly increase the viscosity of displacement fluids (water or saltwater), reduce the flowability ratio of water to crude oil (flowability ratio=water viscosity/crude oil viscosity), promote displacement fluids more evenly, and expand the volume (covering more oil containing areas).

Viscoelastic profile control, blocking high permeability channels

The network structure formed by cellulose molecules has viscoelasticity and can generate the "Jamin effect" (resistance to the flow of bubbles or droplets in pores) in highly permeable formations, blocking the channeling channels and forcing the displacement fluid to flow towards low-permeability areas, driving out more residual crude oil.

Reduce interfacial tension and promote crude oil stripping

Some cellulose derivatives, such as carboxymethyl cellulose, can adsorb at the oil-water interface, reducing the adhesion between crude oil and rock surfaces, making it easier for crude oil to be stripped from rock pores and carried out by displacement fluids.

Summary: The core value of cellulose in improving oil recovery rate

celluloseBy regulating fluid viscosity, stabilizing system performance, and improving the interaction between fluid and reservoir, its derivatives play a role in three key processes: drilling (protecting reservoir), fracturing (expanding fracture flow), and tertiary oil recovery (improving displacement efficiency), achieving an increase in crude oil recovery rate. Its advantages lie in its wide range of sources, low cost, good biocompatibility (easy degradation, minimal environmental impact), especially in the exploitation of low-permeability and unconventional oil and gas reservoirs (such as shale oil and tight gas), it is a green oilfield chemical with application value.

TEL:+86 (0311) 8444 9786

Email:sales@double-bulls.com

Email:Export@double-bulls.com

Address:No.9 Weisi Road, Jinzhou City Eco-nomic Development Zone, Shijiazhuang City, Hebei Province.

Website

Brochure

Video